Ryder Industries

Working to Become the Factory of the Future

Ryder Industries

Working to Become the Factory of the Future

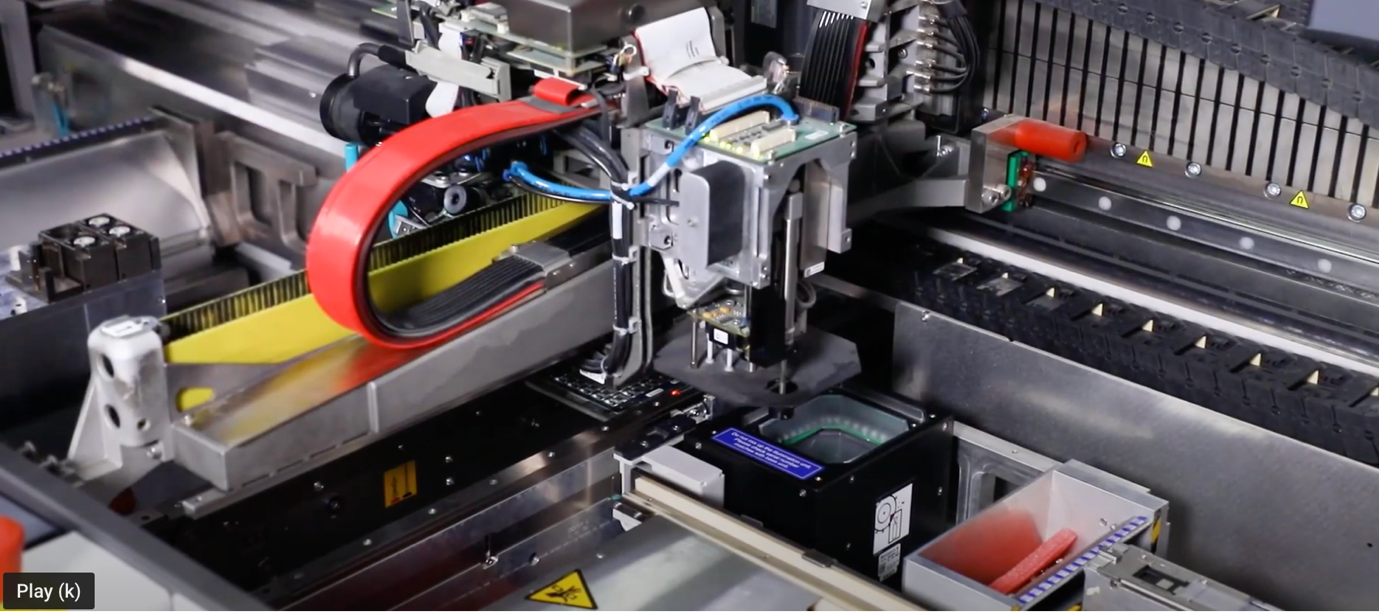

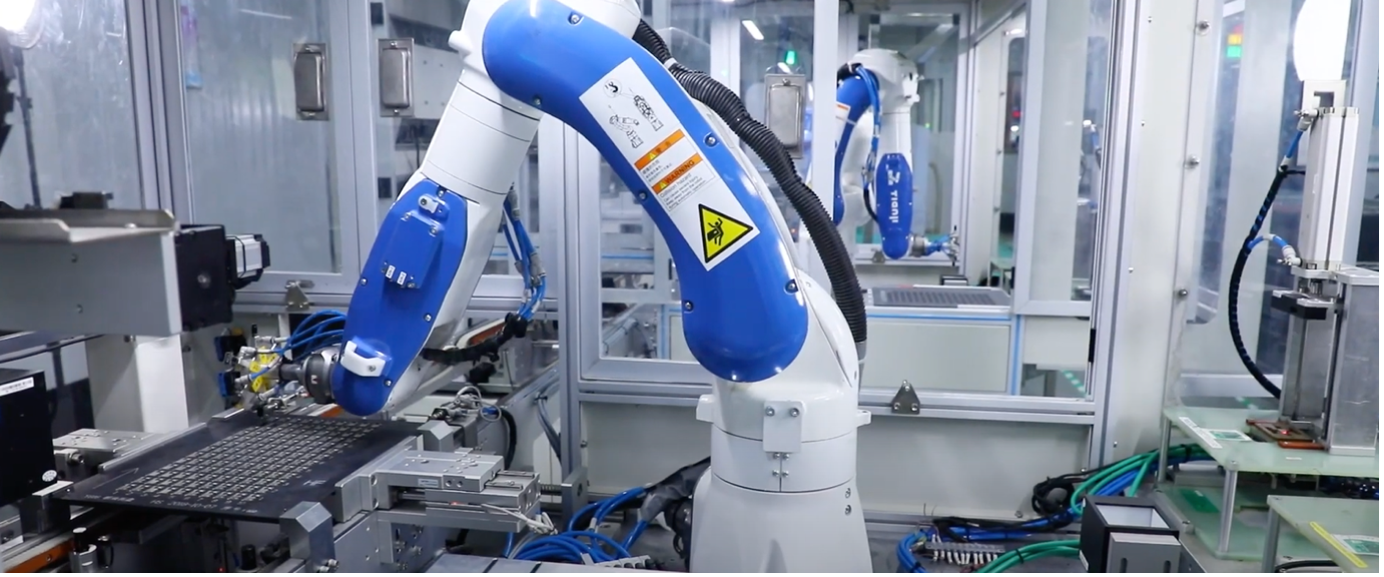

Ryder Industries has made significant investments over the past half century to automize our repetitive production operations in keeping with our ethos to continuously improve, whilst working to LEAN and Six Sigma principles and practices, in parallel with meeting our objective to become the smart factory of the future.

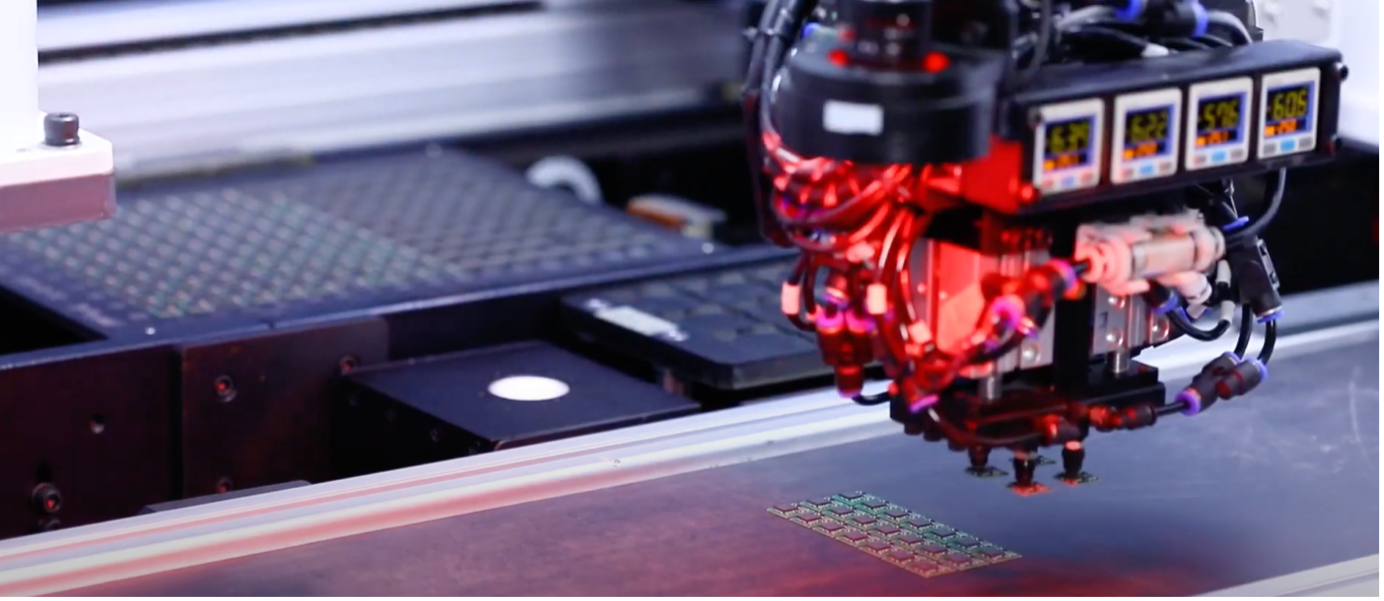

The 'Smart Industry' is a synonym for Industry 4.0 or industrial transformation in the fourth industrial revolution within which smart manufacturing de facto fits.

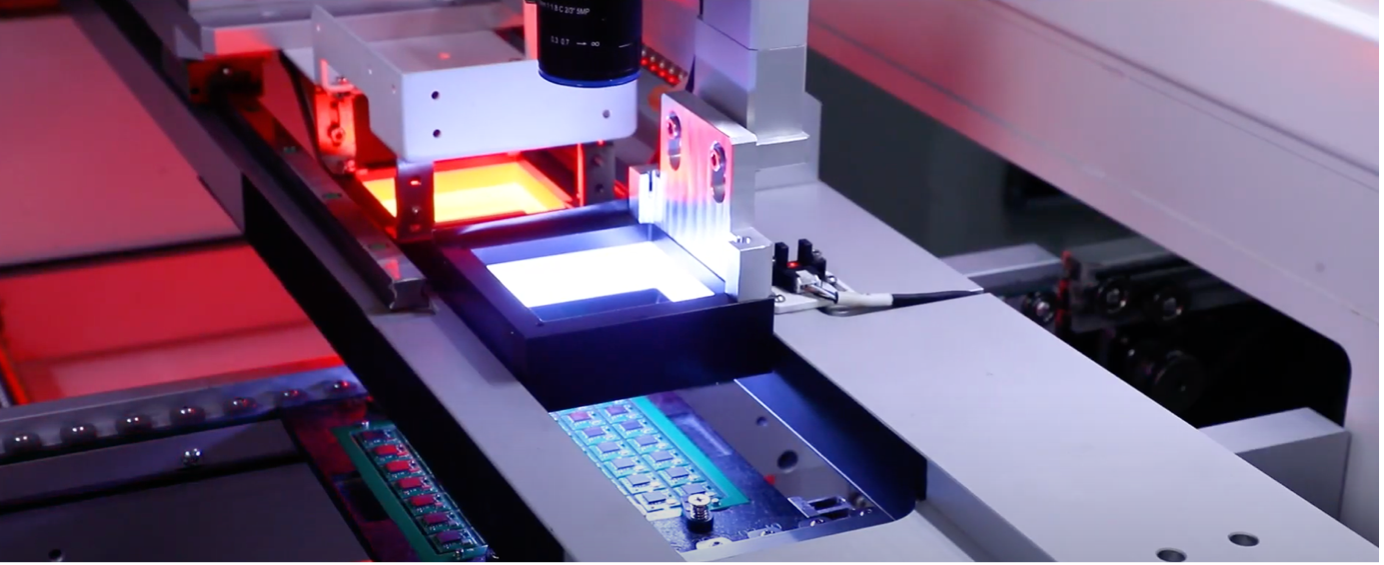

The digitization in manufacturing is becoming a Smart Factory that is a highly digitized shop floor. Via this transformation we continuously collect and share data through connected machines, devices, and production systems.

This means we have fully integrated operations and collaborative manufacturing systems that respond in real-time to meet changing demands and conditions in our smart factory, benefiting our supply chain network and delivering in accordance with our customers' actual needs and forecast requirements.

Competitive advantage comes from the continuous improvements we make to streamline our production efficiencies. By eliminating repetitive processes, utilizing intelligent automation our workflows are streamlined which boosts their efficiency and in turn, enables our customers to benefit from our manufacturing efficiencies from seed to scale, as well as to further ensure we deliver the best quality product to our customer.

The Benefits of Our Smart Manufacturing Environments

Ryder has made the conscious decision to integrate our systems, processes, technologies, and personnel to enhance the management of our building's facilities (name locations).

Like virtually every other aspect of industry, facilities management and equipment will be transformed by digital technology over the coming years. From sensor devices in the office to track utilisation to large form factor capital equipment used in manufacturing facilities, the need to make data-driven decisions and gather intelligence is growing in momentum. In the supply chain of everything, the need for full transparency and traceability back to batch is in demand.

The smart and connected world will ease tasks, and, in the workplace, yes, it could reduce repetitive process production staffing levels, however, this enables companies like Ryder to present the opportunity to upskill their labour intensive, manual tasks.

The above becomes a strong competitive advantage in making our workplace a more attractive place for employees and a more attractive talent acquisition and retention offering due to the level of data we can provide to our customers 24/7.

In terms of real-time data, we are able to monitor our:

Benefits:

address issues with current functional systems, which will reduce daily as well as unnecessary expenditure.

All of these have a knock-on impact to efficiency, which drives economics and a competitive advantage.